- Use cases

- Smart Cold Chain Use Case

Smart Cold

Chain in South Korea

Smart Cold Chain – Challenges and Overview

This case study revolves around the application of new, high penetration wireless IOT

technologies to sensing temperatures at and around assets across warehouse floors

Thing+ helps centralize the data for monitoring and analysis, with value extracted

through the immediate, intelligent usage of this consistent data

Introduction

01In the most cold storage warehouses, there are a variety of products that all require very

specific storage temperatures

02Business owners and partners in the “Cold Chain” (including cold storage warehouses,

logistics, and point of sale) require centralized and automated tracking of temperatures

and product to comply with regulations as well

as ensure their assets

03Temperatures across the entire warehouse must be measured and analyzed

continuously to prevent product loss and to pinpoint problem areas. Due to the constant

movement and changes inside the warehouse, immediate and consistent confirmation

of temperature data is critical

USE CASE BENEFITS

Reduction in Product Lost

Reduction in Cost of Labor

Reduction in Energy Costs

Improved Product Quality (Food)

Improved Customer Safety (Food)

Solution Overview

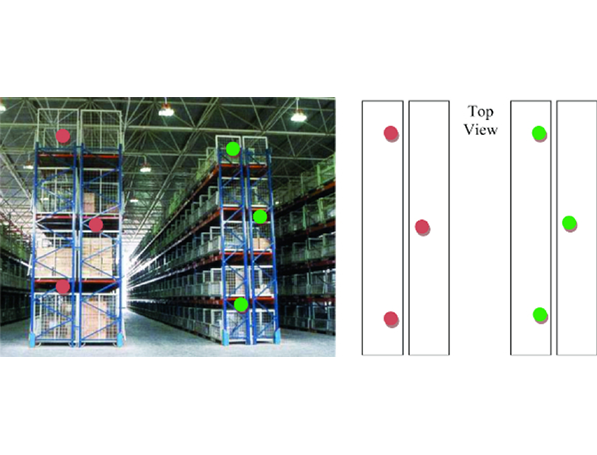

01Placement of a large number of temperature probes capable of long range, high penetration

data uplink in critical positions across the warehouse

02Automate temperature data to immediately warn operators and stakeholders of

potential issues via SMS

03Provide flexibility to operators to change sensor locations and rules to follow changes in

warehouse product & conditions

04Provide the backend and APIs required to integrate and analyze the data

with pre-existing systems

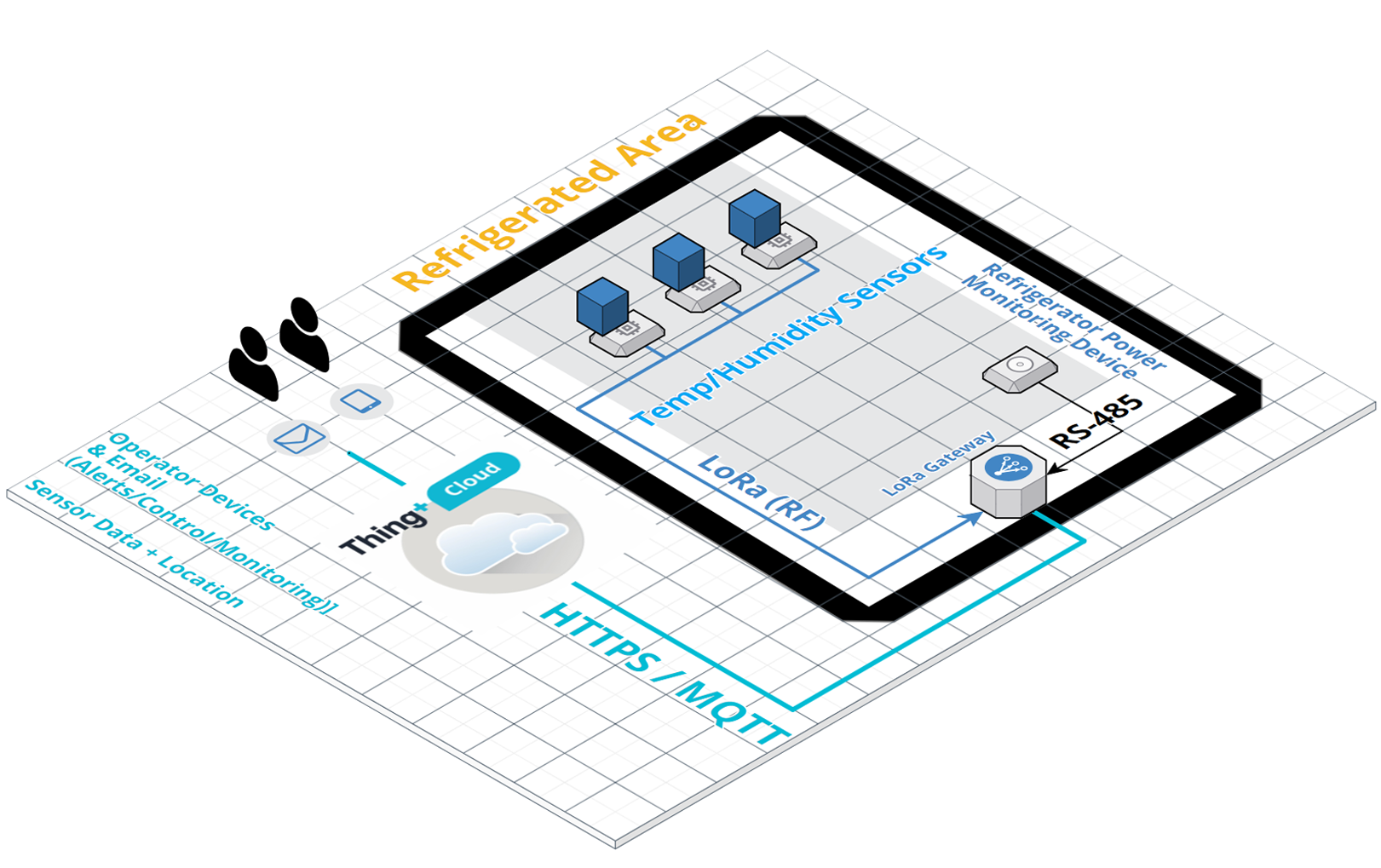

System architecture

The below images show the hardware and software used to create the full end-to-end

solution. The core UI and UX modules of the Thing+ web application were used in this

specific case. S-47 edge nodes from partner Maestro Wireless were used for reliable,

consistent temperature monitoring beside pallets and warehouse assets

HARDWARE DETAIL

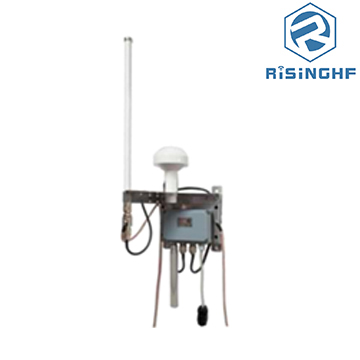

Gateway

Rising HF

LoRa Gateway_industry

Sensor Node

Maestro

Wireless – S-47

SYSTEM APPLICATION AND

OPERATION EXAMPLES

SYSTEM APPLICATION AND

OPERATION EXAMPLES

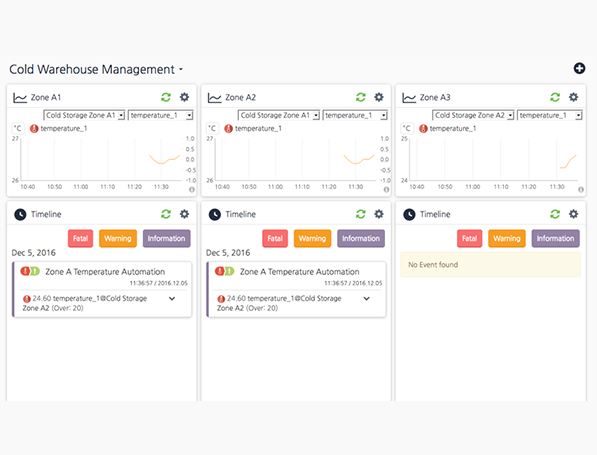

Warehouse Internal “Full Picture” Dashboard

The Thing+ dashboard is used as a “full picture” dashboard to check all current

temperatures at the warehouse on a minute-by-minute basis Historical timelines

including abnormalities in temperature and unexpected temperatures at different

parts of the warehouse are shown on a per-zone basis

SYSTEM APPLICATION AND

OPERATION EXAMPLES

SYSTEM APPLICATION AND

OPERATION EXAMPLES

Back-End Integration

The Thing+ API was used to export historical data from the temperature sensing edge

nodes to 3rd party systems for data analysis. This data was used to inform changes to

the floor layout of the warehouse

SYSTEM APPLICATION AND

OPERATION EXAMPLES

Back-End Integration

The Thing+ API was used to export historical data from the temperature sensing edge

nodes to 3rd party systems for data analysis. This data was used to inform changes to

the floor layout of the warehouse

SYSTEM APPLICATION AND

OPERATION EXAMPLES

SYSTEM APPLICATION AND

OPERATION EXAMPLES

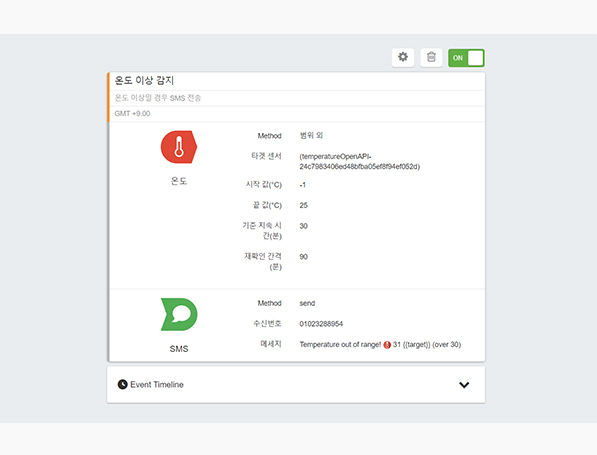

Automation and Alerts

Alerts were created triggered whenever temperatures at any zone became abnormal. In most cases, the Thing+ API was also used to directly

automate the A/C units when significantly abnormal behavior was detected – this was especially important during “off-times” when

most workers were not on-site (generally after midnight until the morning)

An example data-push rule used to help control the system based on sensor status data

Contact us

line

궁금한점이있다면 메세지를 보내주세요!

Do you have any questions?

Address : 10F Younghan-Building 12, Jung-gu, Supyo-ro, Seoul 04554

Telephone: +82. 2. 2274. 3254

Fax: +82. 2. 2274. 3254

Email: contact@daliworks.net

오류: Contact form not found.